Digital Dentures Made Simple: 4 Workflow Tips That Actually Work

Why Digital Dentures Matter

Digital dentistry isn’t the future anymore — it’s the present. Today, digital impressions and CAD/CAM workflows are transforming the way clinicians and labs collaborate to deliver prosthetics.

But while digital tools promise speed and precision, poor workflows can lead to costly remakes, frustrated patients, and wasted chair time.

At Denture Crafters, we’ve worked with hundreds of clinicians and thousands of cases. The difference between success and failure often comes down to the workflow itself.

In this article, we’ll break down the essentials for:

Getting accurate digital impressions

Following a proven digital denture workflow

Improving patient acceptance with chairside confidence

Understanding when and how to add analog steps for extra accuracy

What Are Digital Dentures?

“Digital dentures are removable prostheses fabricated using CAD/CAM technology. They begin with a digital impression or scan of the mouth and are designed virtually before being milled or 3D printed.” -(Cleveland Clinic)

Unlike traditional dentures, which require multiple impression stages and physical wax try-ins, digital dentures rely on:

Scans instead of impression trays

STL files instead of stone casts

Digital design software instead of manual wax-ups

Milling/printing instead of flasking and packing

👉 Explore our Digital Denture Services to see how we embrace the Digital Denture Revolution with Denture Crafters

At Denture Crafters, we’ve seen what works (and what doesn’t). Here are our top tips to help your digital cases go smoother, faster, and with higher patient acceptance.

Tip 1. Nail the Fit: Impression Accuracy Still Matters

Even with digital, garbage in = garbage out. The #1 cause of denture remakes is poor scans. Follow these essential steps to set yourself up for success:

✅ Dry thoroughly before scanning. Moisture creates “holes” in data capture.

✅ Capture borders clearly — vestibule, hamular notch, frenums, all soft tissue extensions.

✅ Go slow & overlap passes — speed introduces distortion; overlapping ensures continuity.

✅ For partials, scan everything — rest seats, undercuts, clasps.

Not sure where to start?

Tip 2. Follow the Digital Workflow — Order Matters

Digital workflows succeed when followed step-by-step. Skipping or reordering introduces errors. Think of digital like baking — order matters. Here’s the proven sequence:

Scan upper and lower arches

Capture the bite (use bite registration if needed for accuracy)

Send STL files directly via your scanner or secure upload link

Include photos (smile, lip at rest, occlusion shots)

Provide clear Rx instructions —list what we’re fabricating and which materials you prefer

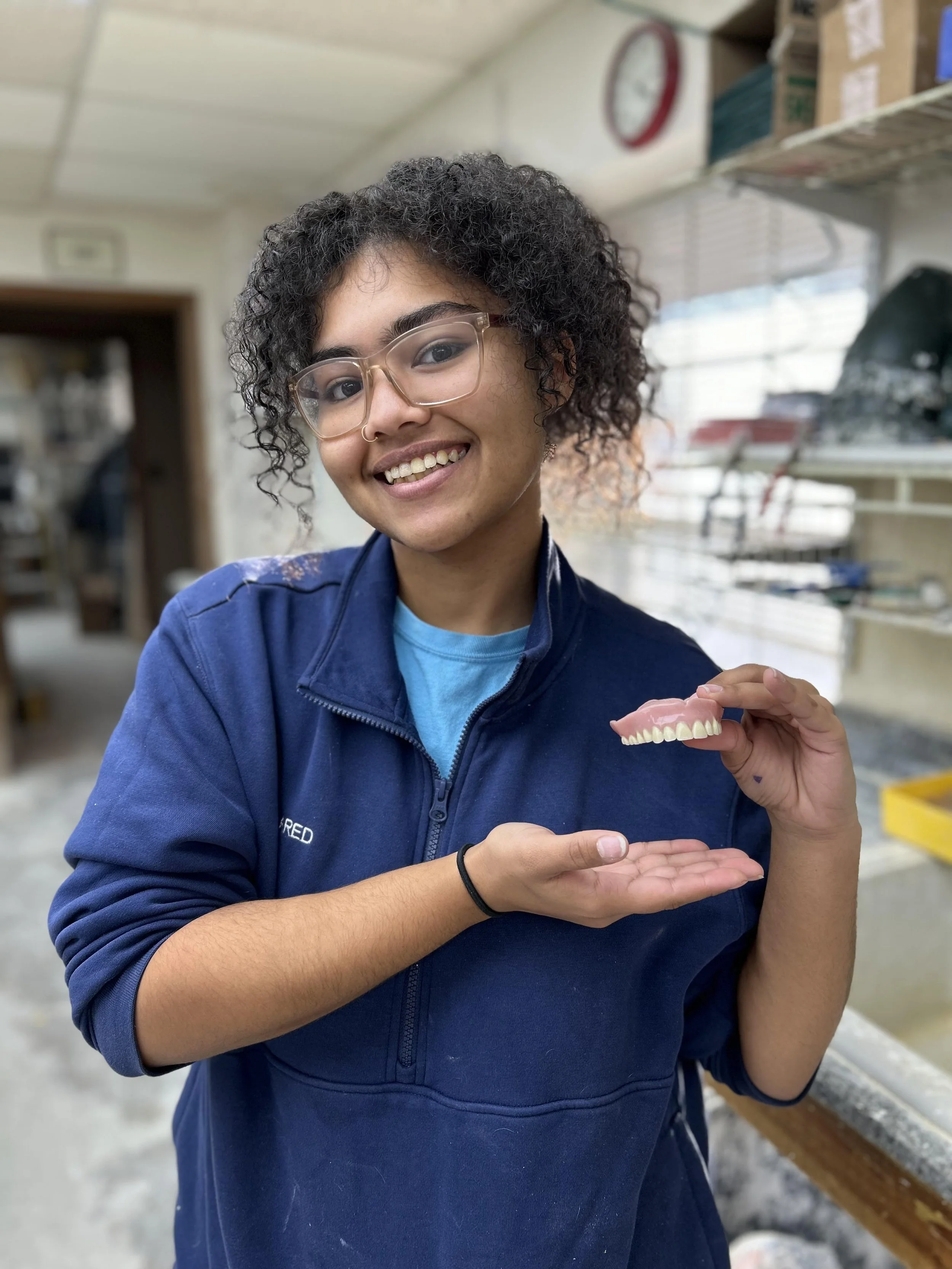

Pictured:

Monolithic digital try-in custom built at Denture Crafters

Bonus Tip: If you’re doing a baseplate and rim stage, take a light body wash impression inside the baseplate. This creates an even more accurate foundation and eliminates guesswork at the final stage.

Tip 3. Improve Case Acceptance with Chairside Confidence

Digital dentistry isn’t just about lab accuracy — it’s also a powerful patient acceptance tool. Patients are more likely to say “yes” when you can promise:

✅ Faster turnaround times (3-day digital turnaround with Denture Crafters!)

✅ Fewer visits thanks to digital consistency

✅ Visual Preview mockups or digital try-ins to “see before they say yes”

Bonus Perk for Patients

If the try-in fits well and the patient is happy, they get to keep it as a backup denture. It’s peace of mind they’ll love — and an extra value-add for your practice.

Tip 4. Combine Digital & Analog for Maximum Accuracy

While digital impressions dominate, analog impressions still play a role:

Digital excels at speed, storage, and repeatability.

Analog excels when recording extremely mobile soft tissues or in cases where scanners struggle with reflective surfaces.

According to NCBI research on digital impressions, hybrid workflows (digital + analog) often yield the highest success rate for complex prosthetics.

Reference: Digital impression accuracy study – NCBI

Why Partner with Denture Crafters?

At Denture Crafters, we make digital dentistry work for you, not against you!

After 30+ Years partnering with dentists, here’s what sets us apart:

🦷 We accept STL files from any scanner

🦷 We support both new digital users and advanced clinicians

🦷 We offer step-by-step guidance for tricky cases

🦷 Same-week turnarounds so your patients don’t wait

🦷 First case special: Get 50% OFF your first case with Denture Crafters

Final Thoughts

Digital dentures may feel complex, but with the right workflow, they’re not only manageable — they’re a growth opportunity for your practice. By mastering impression accuracy, following a proven digital workflow, and leveraging patient-facing benefits, you’ll deliver faster, more predictable results with higher patient satisfaction.

At Denture Crafters, we’re here to be your digital partner — offering both the technology and the technician support you need to make every case a success.

📞 Ready to get started? Contact our team today and let’s simplify digital dentures together.